Production automation

The main tasks of laser sensors in this area are the identification of assembly components, monitoring of assembly processes, presence checking, and inspection by variables.

In the field of axle drive shaft production, a large variety of shafts run over one production line, so that it is necessary that the type of shaft is communicated to the lathe for automatic setting of the machining parameters. This identification is carried out by a laser distance sensor, which is integrated in the conveying line, and which identifies the shaft type by shape, position and length of the metal slugs and communicates it to the CNC machine.

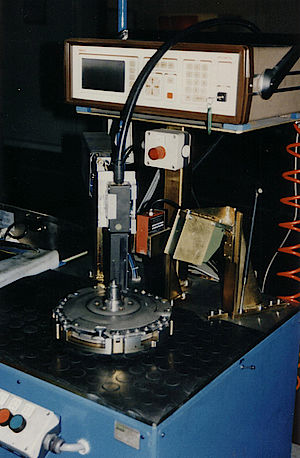

Also for clutches a combined inspection by variables and presence check is carried on the basis of a distance measurement. So, during the passage of a clutch disk, criteria such as type of inserted hub, completeness of assembly components (springs, sheets, etc.), and coating thickness are detected.