Research and development

Measuring of wheel position

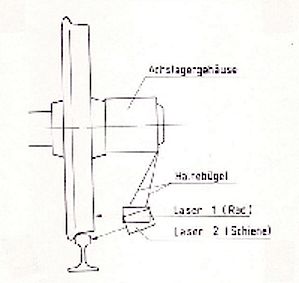

The high scanning frequency of the OPTImess sensors (up to 50 kHz) provides the possibility to scan the wheel's outer side. By the defined positioning of the sensors at the sides of the railtracks, the recording of the wheel-sets' positions within the rails is possible at high speed. With this kind of in-line positioning of several sensors within the area of points, it is also possible to reach conclusions about the running behaviour of wheel-sets in points and to optimise guides inside of points.

Behaviour wheel / rail

Other applications

- Measuring of rail movements

- Approach measurements during wagon connecting

- Heeling measurements of wagon superstructures

- Recording of the current-collector position

These examples of application have been listed to point out the diversity of the OPTImess sensors for measuring processes in railway practice. The variety of measuring ranges (4-800 mm), high scanning frequencies (up to 50 kHz), small size, and operating possibilities on nearly all kinds of surface, as well as insensibility with regard to impact stress, are properties which have turned laser sensors into an universal sensor for measurements in the area of wheel/rail. Many kinds of application are also transferable to measuring tasks in underground and local transport organisations.