Mobile measuring system for wheel profile measuring

Requirements for wheel profile measuring

Wheels - one of the most important structural component of all rail vehicles - are subject to high mechanical stress and by this have considerable influence both on the running performance and riding comfort of the various kinds of vehicles. The wheel-rail-system is subject to a wide range of requirements and controls to ensure the required operational reliability.

Furthermore, the mechanical wear due to friction is a cost factor not to be disregarded.Therefore control measurements have to be taken in regular intervals, which are still carried out mostly by hand. Thus, subjective measuring and reading errors cannot be ruled out. Based on these criteria, the portable, laser-supported wheel-profile measuring system offers significant advantages for the acquisition of wheel profile parameters at a non-moving wheel.

Advantages

- high-speed practicability of high-precision measurements

- evaluation and on-the-spot diagnosis of the wheel-profile working condition at mounted wheelsets

- elimination of subjective measuring and reading errors

- recording and qualitative evaluation of the entire wheel profile, no limitation to only a few check points

- immediate determination and display of wear parameters

- high mobility of the measuring system

- simple and uncomplicated handling capability

Measuring System in Operation

- abrasion-free, high-precision, non-touch measuring system

- suitable for the most confined spaces

- no calibration adjustments necessary

- operable independent of mains supply

Cost factor Wheel Profile Wear

Long-term analyses of wear parameters and wheel profile checks provide supporting information for the determination of low-wear wheel profiles. Optimum vehicle running periods (until re-profiling) can be determined on the basis of the wear behaviour.

Portable Wheel Profile Measuring System

Acquisition of profile measurement data of wheel profiles of different dimensions and in the most confined spaces is ensured by a laser-supported measuring system. With the aid of a data storage unit the allocation of nominal and limit sizes for the respective type of profile is carried out. Measurements at the wheel, and wear evaluations can be performed within a very short time.

Principle of Measurement and System Components

For quick wheel contour checks by repetitious measuring during servicing various mobile systems, based on the OPTImess laser measuring system, have been developed in co-operation with Deutsche Bahn (DB). This state-of-the-art generation of appliances is operating independently of the electric network with 4 pcs of 1.5V Mignon accumulators. With this device up to 150 wheels can be measured without changing of batteries. The measuring data are stored at the vehicle on a Datalogger MINI-LOG 1 and transferred via network or the Internet to the server.

The capturing of the wheel-contour measuring data, such as wheel flange thickness and height, qR-measurement, wheel diameter, etc., is guaranteed - even in case of very small free spaces at the wheel and varying dimensions - by the laser-based measuring device. Aided by a data base, the allocation of the index and limit values to the respective type of contour is carried out and monitored. As an optional feature, the complete contour graph for wear indication measuring can be created. Due to its small size, the system can also be used on modern low-ground tramways.

Measuring Process and Error Detection

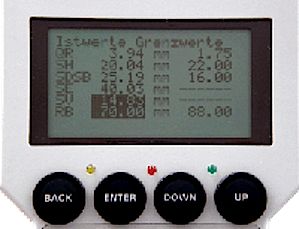

The operator is supported by comprehensive information about the measuring process and the measuring results. The measuring result is displayed in relation to the warning and limit values by comparison. On exceedance of a measured value it will be displayed inverse.

Rail measurement

With an esay to fix adapter to a track wdth gauge it is possible to measure also Vignol or Grooved Rails.

Equivalent conicity according to UIC519

The software tool RSGEO is for analyzing the kinematic of a wheel set on rails as a function of the lateral movement considering the elastic deformation of the touching area with a normal force.

Options

- average wheel diameter

- monitoring of differences in wheel diameters of the entire vehicle, of the driving gears and trucks

- acquisition and monitoring of rail head profiles

- interfaces to mainframe EDP-systems for data transfer

- runout measurement

- rail measurement

- equivalent conicity according to UIC519