Robots industry

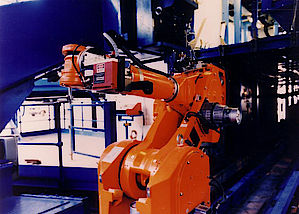

Here, the laser sensors are used for exact positioning of the robots for drilling, riveting, welding, and assembling tasks. In this way, the robots, which are in use in aircraft assembly for automatic drilling and riveting, are newly refered via laser sensors in short intervals because a positioning in the 1/10mm-range has to be guaranteed also for longer travels.

In connection with welding robots, laser sensors assist with edge detection in lap seam welding by exact positioning of the welding beads.

In welding the OPTIscan laser scanner offers advantages because it facilitates two-dimensional measurements. While the standard triangulation sensor carries out a spot measurement, the light beam in laser scanners is diverted via an internal mirror system, so that distance measuring along this line is feasible.

In this way, online weld seam scanning becomes possible. Another application option of the OPTIscan is the surface measurement of weld seam joints (for example on laser-welded injection nozzles). But laser scanners are also used for measuring of the build in tear-open spot for airbags in controlled-collapse steering columns.

Further applications in connection with assembly robots are the automatic positioning during car-door fitting (OPTIscan), and the checking of sealing beads at motor units, which are automatically placed by means of a robot.

In the packaging industry, laser sensors assist in the automatic de-palletising of empty bags for the building industry, which are then conveyed full-automatically to a bagging plant.