Thickness measurement with laser sonsors

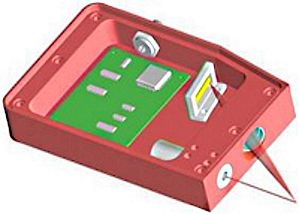

Punctiform OPTImess laser triangulation sensors, OPTIscan laser triangulation scanners or light section sensors and OPTIline shadow measuring systems are used here. In laser triangulation a laser point or in scanners and light section sensors a line is projected onto the material. This point is transmitted to a detector by a receiver optic fitted underneath a bracket. This may be a PSD (Position Sensitive Device) or CCD (Charged Coupled Device) detector.

The PSD-detector offers the greater measuring frequency (bandwidth), the CCD-detector on the other hand has lower noise and therefore higher sensitivity. By selective reading out of the pixels an exact division between the surface reflection and reflection out of the material is possible. This is particularly important with partially transparent materials.

In the triangulation scanner the principle of the punctiform laser sensor is deflected over a distance by a system of mirrors in the sensor.

The lateral position is given here as a measured value in addition to the distance information so that the thickness or thickness profile along the scanned line is recorded. Similarly to with the laser scanner the measurement in the light section sensor is also made along a line except that in this case the line is generated by optical widening of a laser point. The line dispersed diffusely from the object surface is projected on a CCD-matrix detector (similar to a CCD-camera).

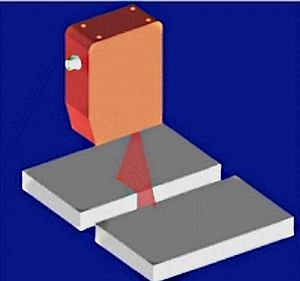

Thickness measurement according to the shadow principle with OPTIline sensors. In the shadow principle a laser line of parallel light is generated and projected on a CCD-line opposite. When a material is inserted in the measuring gap this leads to a partial shadowing of the laser line on the detector. For thickness measurement it is necessary for the material to be measured to be deflected by a roller. The difference between the roller (zero) and the material surface picked up by the shadow measurement system is the material thickness.

The advantages of the laser measuring technique in the field of thickness measurement are:

- no material contact

- independent of the colour of the material by control of the laser power

- independent of the composition of the material

- high local resolution due to small measuring spot

- high measuring frequency (up to 50 kHz)

- great distance from material possible

- measurements on hot surfaces possible

The measurement is restricted on completely transparent materials. This is only possible with a special laser sensor which operates in direct reflection.