The increasing automation of casting processes necessitates a more exact adjusting of the meniscus level all the time. Level control is mainly effected by various kinds of float regulator systems. The fact that these systems are in direct contact with the molten mass is the cause for sources of disturbance, as for example adherent materials.

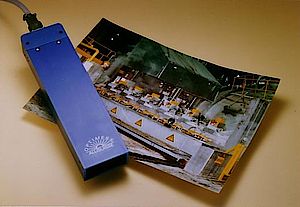

For the use in measurements on molten mass surfaces, special OPTImess sensors are available. According to the environmental temperature, the sensors are operated with air- or water-cooled casings. For measurements on molten aluminium surfaces, solely air-cooled sensors are used, whereby the cooling air emerges in the area of the optical-system, keeping it clear from rising vapour at the same time.

For the use in measurements on molten steel mass, water-cooled sensors with additional air rinsing for the lens system are in operation. In addition, the detectors are equipped with interference filters and an internal thermal protective-system.

The measuring ranges are between 100 mm and 400 mm at distances between the sensor and the centre of the measuring-range (stand off) of up to 800 mm. The analogue output signal (current or voltage) can be used directly for stopper control. When continuous casting moulds are in use, the wide measuring range facilitates the floor detection in front of the sprue and level control measurement during the entire cast-on period.

Here, laser systems operating in non-contact technique are advantageous because, apart of not coming into contact with the molten mass, they also present further advantages - as for example a wide measuring-range and a considerable basic distance to the surface of the metal.

The main areas of application are the meniscus level control in

- melting furnaces,

- continuous casting moulds,

- launders,

- plants for continuous casting of hoop steel,

- mould casting.